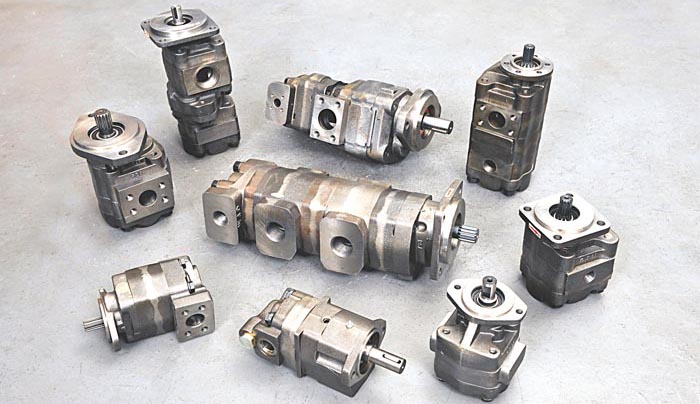

We manufacture a range of Bearing, Bushing, PTO Truck Pumps and Flow Dividers. We also manufacture a complete range of internationally interchangeable commercial components for Bearing pumps, Bushing pumps, Motors and Flow Dividers.

- Our pumps and parts are of exceptional quality.

- Our equipment is provided at an economic cost.

- We are proud of our fast response time and quick delivery times.

- We maintain a comprehensive stock-holding of spares.

- We carry out in-house porting to exact customer requirements.

- We have a professional custom-design capability at your service

- We deliver internationally.

- We support well-stocked Distributors in USA, UK and Australia.

We began filling the shelves with inventory to support our North and South American customer base and on April 1, 2016, we officially opened.

Establishing this supply chain warehouse has allowed our western customers to reduce their inventory dollars and the quicker ship time has given GPM-US a greater position in the market.

- Pump Design

- Precision Casting, Engineering and Machining

- Custom Hydraulic Pump Design and Manufacture

- Pump Rebuilding

- Gear Set Manufacture

- Thrust Plate Manufacture

- Continuous Process Improvement to ISO 9001:2015 standards

The company manufactures and offers a comprehensive range of pumps to meet specific customer requirements as well as those of the general market.

The products displayed on this site are summarized in the following product ranges:

- Hydraulic Bearing Gear Pumps

- Hydraulic Bushing Gear Pumps

- Hydraulic PTO Bearing Pumps

- Hydraulic PTO Dump Pumps

- Flow Dividers

- Add-a Pumps

- Step-Down Pumps

- Replacement Parts

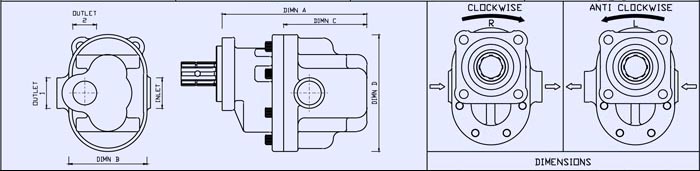

The company manufactures and provides pump design services for customers needing customized solutions.

We handle design from specification to final blueprints and will manufacture custom-built pumps from these plans if the customer wishes to place an order.

GPM’s full range of gear-set product complies with the international standard, ensuring the metallurgical elements of Molybdenum and Nickel are present in the base material for premium quality requirements necessary in hydraulic gear pump applications.

Sectional Construction: Standard parts, cast from high strength grey iron, SG iron, compacted graphite iron (CGI) and bronze cast components can be assembled in a wide variety of configurations to suit almost any application. Superior metallurgical structured CGI material is used in the manufacture of the Higher Pressure requirements of our Bushing Pump Range.

Commissioned in February 2002, our Foundry is located on the same site as our manufacturing facility in Cape Town. Expansion has mirrored that of GPM.

Physically, the foundry has been expanded by more than 50% in order to cater for increased volumes.

Currently the foundry produces Grey Iron, SG Iron and Compacted Graphite Iron. Superior metallurgical structured CGI material is used in the manufacture of the higher pressure requirements of our Bushing Pump Range. The foundries production is dedicated to the requirements of GPM and has sufficient capacity to handle the expected growth into year 2018.

In the interests of the environment and to further contain costs, we invested in a swarf pelletizing machine. Consequently, a large portion of the foundry raw material is obtained by pelletising iron and steel swarf and off cuts from the GPM facility. Bronze castings for the machining of thrust plates are produced in a similar fashion. Reclaimed machining coolants and cutting oils are recycled.

Our operations conform to ISO 14001:2015 Environmental Management standards. See our certificate here

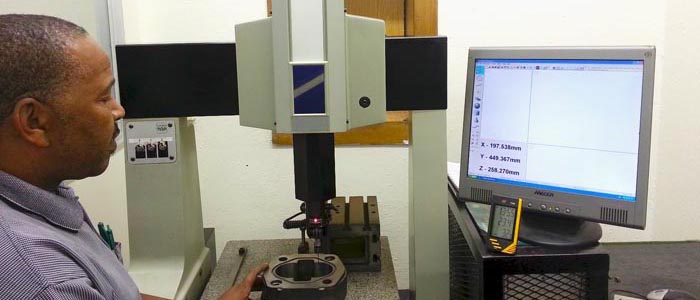

Our quality management system makes use of statistical analyses to determine manufacturing process capability.

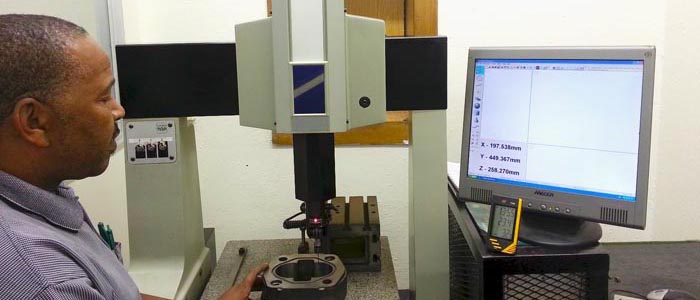

The stability of manufacturing processes is continuously monitored and managed via machine run charts. In line with our technology investment philosophy, we have recently invested in a 3-dimensional co-ordinate measurement machine.

This will increase productivity by means of faster first-off measurement as well as enabling expanded statistical sampling checks.

Our focus is purely on gear pump and motor assembly, ensuring consistently high-quality products. Our plant modernization programme is ongoing. For the past few years we have increased our manufacturing capability and capacity with the latest technological, state of the art, CNC turning, milling, and grinding machinery.

We have porting capabilities to suit the needs of all our customers. Our volumes of pump assemblies have more than quadrupled during the last two years. This necessitated the construction of a new and substantially larger pump assembly area as well as new and upgraded test stands. All assemblies are tested on computerised test stands which have multiple flow, pressure, temperature and speed testing capability.

GPM-US supports our North American distributors and is also able to supply any distributor or customer on other continents if that is quicker or more convenient for them.

We supply and support distributors worldwide, including Algeria, Angola, Argentina, Australia, Belgium, Canada, Chile, Colombia, Ecuador, Egypt, India, Italy, Mexico, Namibia, Peru, Philippines, Saudi Arabia, Singapore, Sudan, Swaziland, Taiwan, Tanzania, Thailand, Turkey, U.A.E, United Kingdom, Uruguay, USA, Vietnam, West Malaysia.

Our production facilities are well established and include a professional design facility and a cast iron foundry on the premises, all operating in accordance with ISO 9001:2015 standards and manufacturing to local and international specifications. GPM has been assessed and certified as meeting the requirements of ISO 9001:2015.

See our certificate here.

Commissioned in February 2002, our Foundry is located on the same site as our manufacturing facility in Cape Town. Expansion has mirrored that of GPM.

Physically, the foundry has been expanded by more than 50% in order to cater for increased volumes.

Currently the foundry produces Grey Iron, SG Iron and Compacted Graphite Iron. Superior metallurgical structured CGI material is used in the manufacture of the higher pressure requirements of our Bushing Pump Range. The foundries production is dedicated to the requirements of GPM and has sufficient capacity to handle the expected growth into year 2018.

In the interests of the environment and to further contain costs, we invested in a swarf pelletizing machine. Consequently, a large portion of the foundry raw material is obtained by pelletising iron and steel swarf and off cuts from the GPM facility. Bronze castings for the machining of thrust plates are produced in a similar fashion. Reclaimed machining coolants and cutting oils are recycled.

Our operations conform to ISO 14001:2015 Environmental Management standards. See our certificate here

Our quality management system makes use of statistical analyses to determine manufacturing process capability.

The stability of manufacturing processes is continuously monitored and managed via machine run charts. In line with our technology investment philosophy, we have recently invested in a 3-dimensional co-ordinate measurement machine.

This will increase productivity by means of faster first-off measurement as well as enabling expanded statistical sampling checks.

Our focus is purely on gear pump and motor assembly, ensuring consistently high-quality products. Our plant modernization programme is ongoing. For the past two years we have increased our manufacturing capability and capacity with the latest technological, state of the art, CNC turning, milling, and grinding machinery.

We have porting capabilities to suit the needs of all our customers. Our volumes of pump assemblies have more than quadrupled during the last two years. This necessitated the construction of a new and substantially larger pump assembly area as well as new and upgraded test stands. All assemblies are tested on computerised test stands which have multiple flow, pressure, temperature and speed testing capability.

GPM-US supports our North American distributors and is also able to supply any distributor or customer on other continents if that is quicker or more convenient for them.

We supply and support distributors worldwide, including Algeria, Angola, Argentina, Australia, Belgium, Canada, Chile, Colombia, Ecuador, Egypt, India, Italy, Mexico, Namibia, Peru, Philippines, Saudi Arabia, Singapore, Sudan, Swaziland, Taiwan, Tanzania, Thailand, Turkey, U.A.E, United Kingdom, Uruguay, USA, Vietnam, West Malaysia.

Our production facilities are well established and include a professional design facility and a cast iron foundry on the premises, all operating in accordance with ISO 9001:2015 standards and manufacturing to local and international specifications. GPM has been assessed and certified as meeting the requirements of ISO 9001:2015.

See our certificate here.