GPM Hydraulic Gear Pumps

Bearing Gear Pump Range

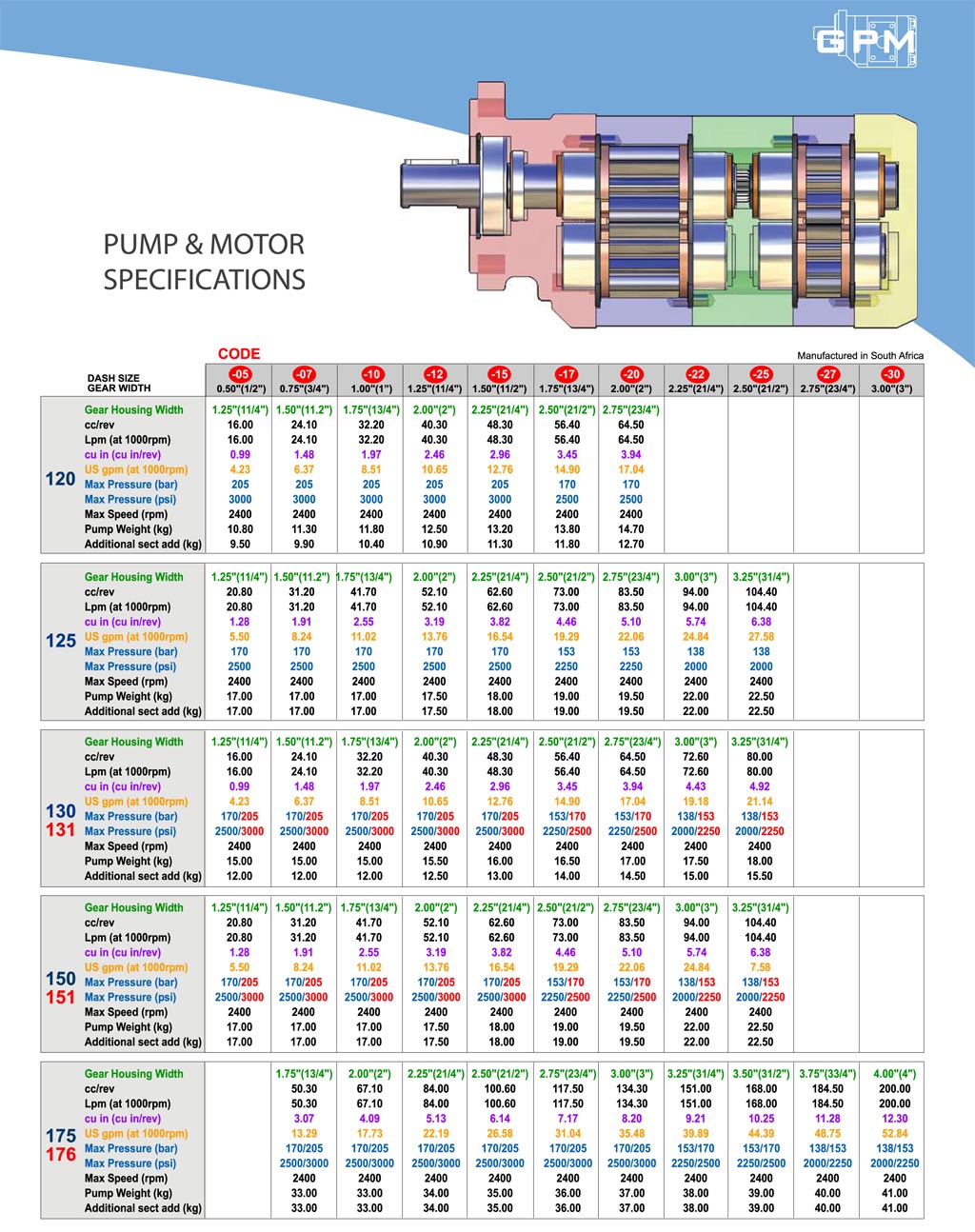

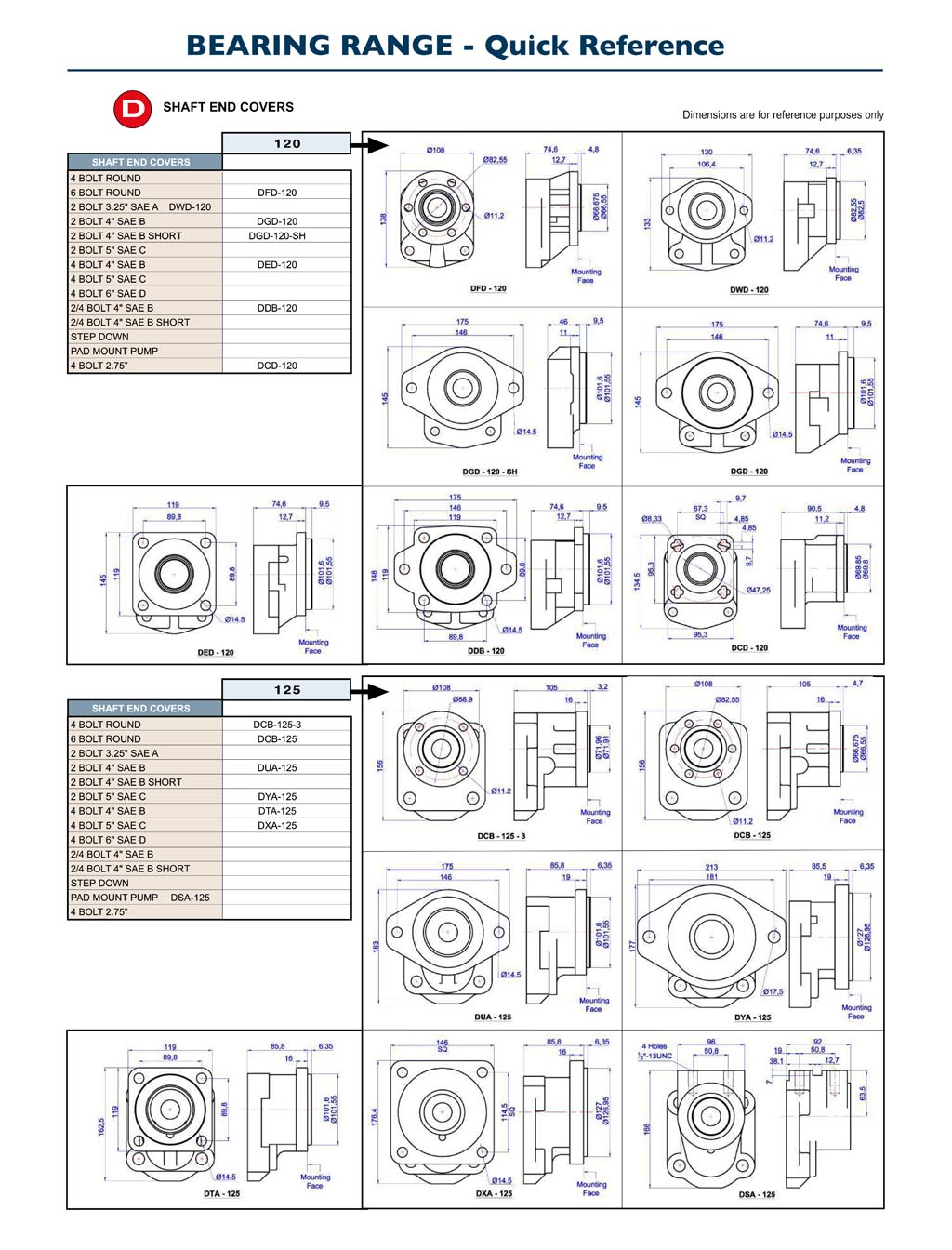

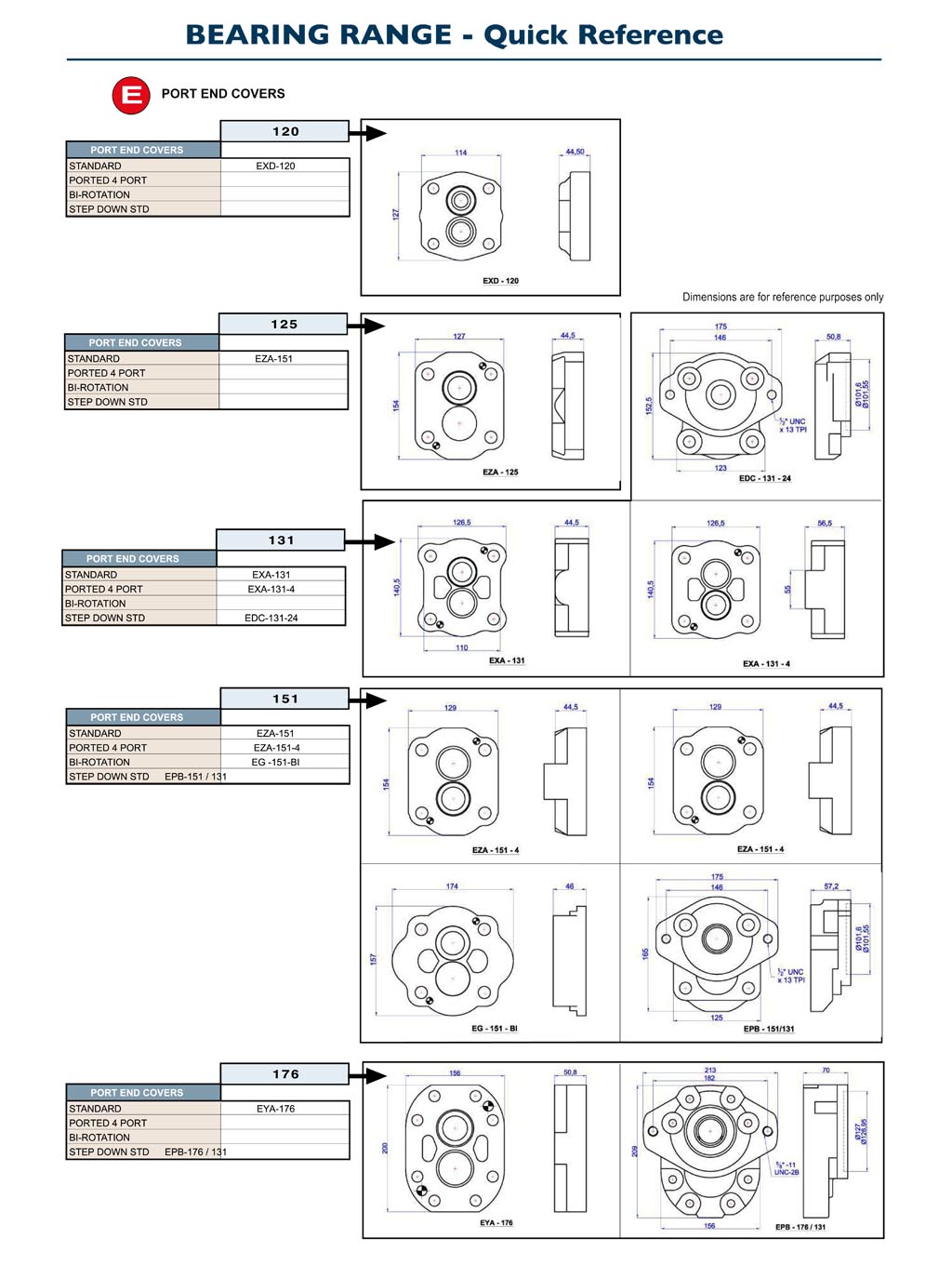

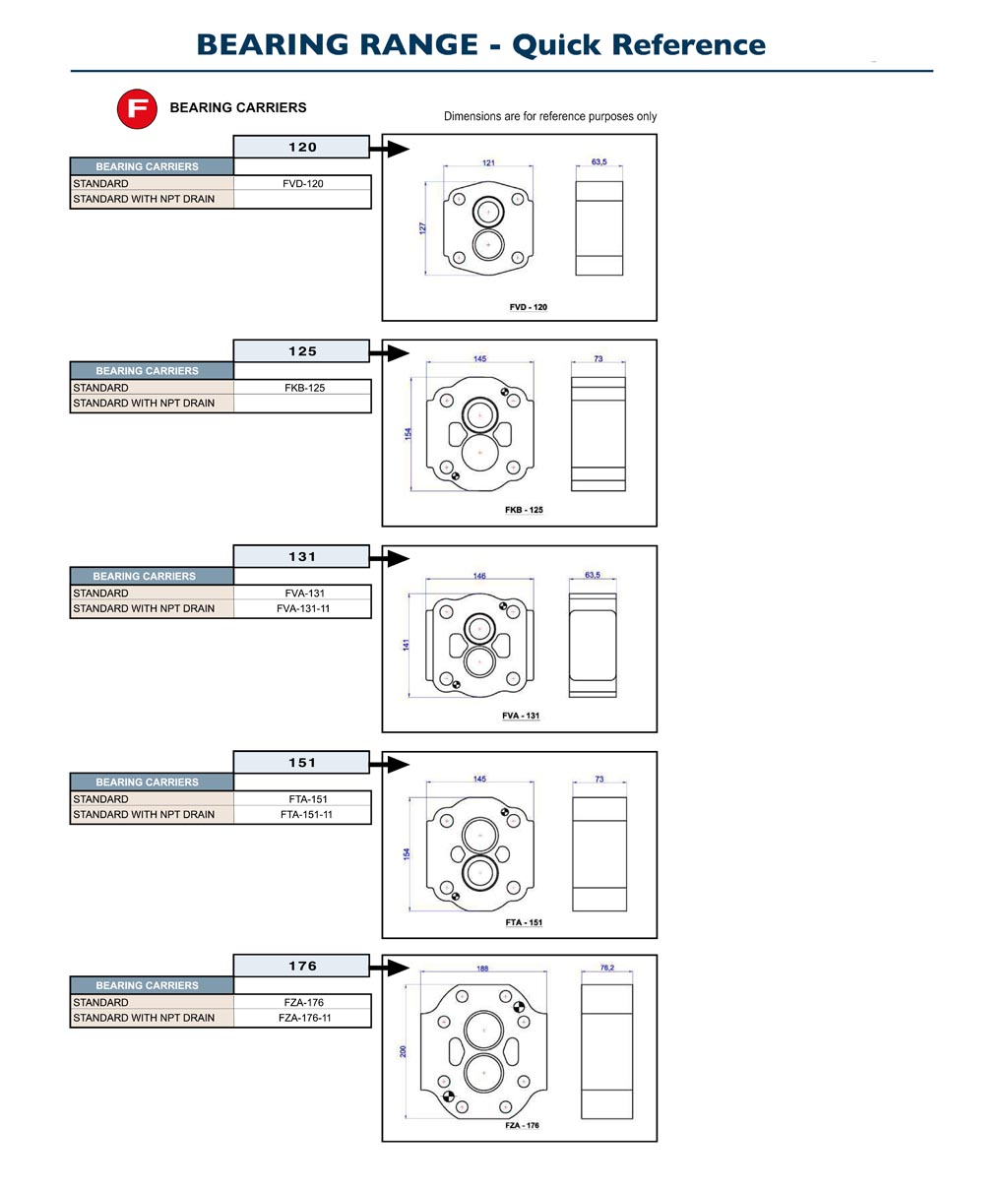

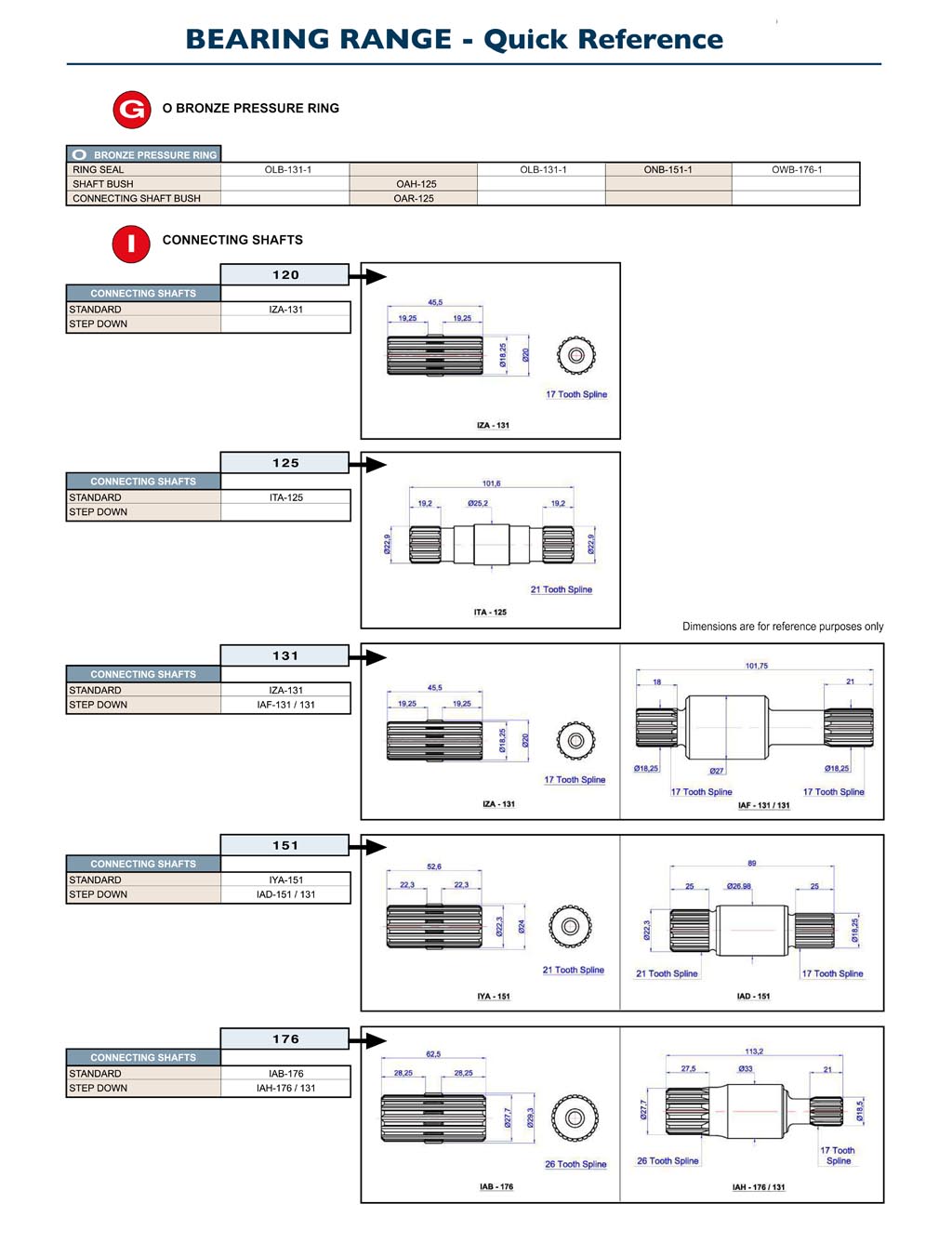

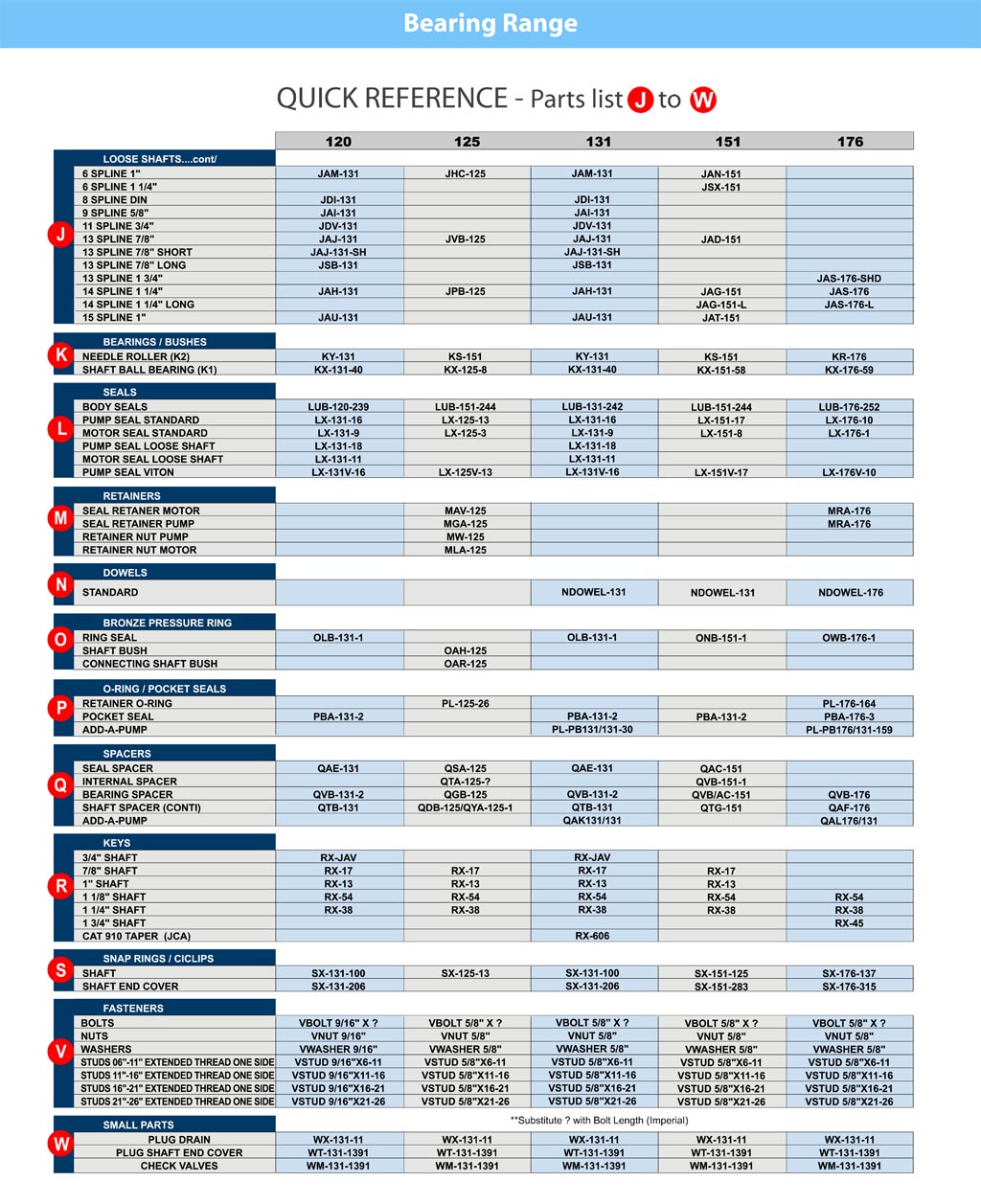

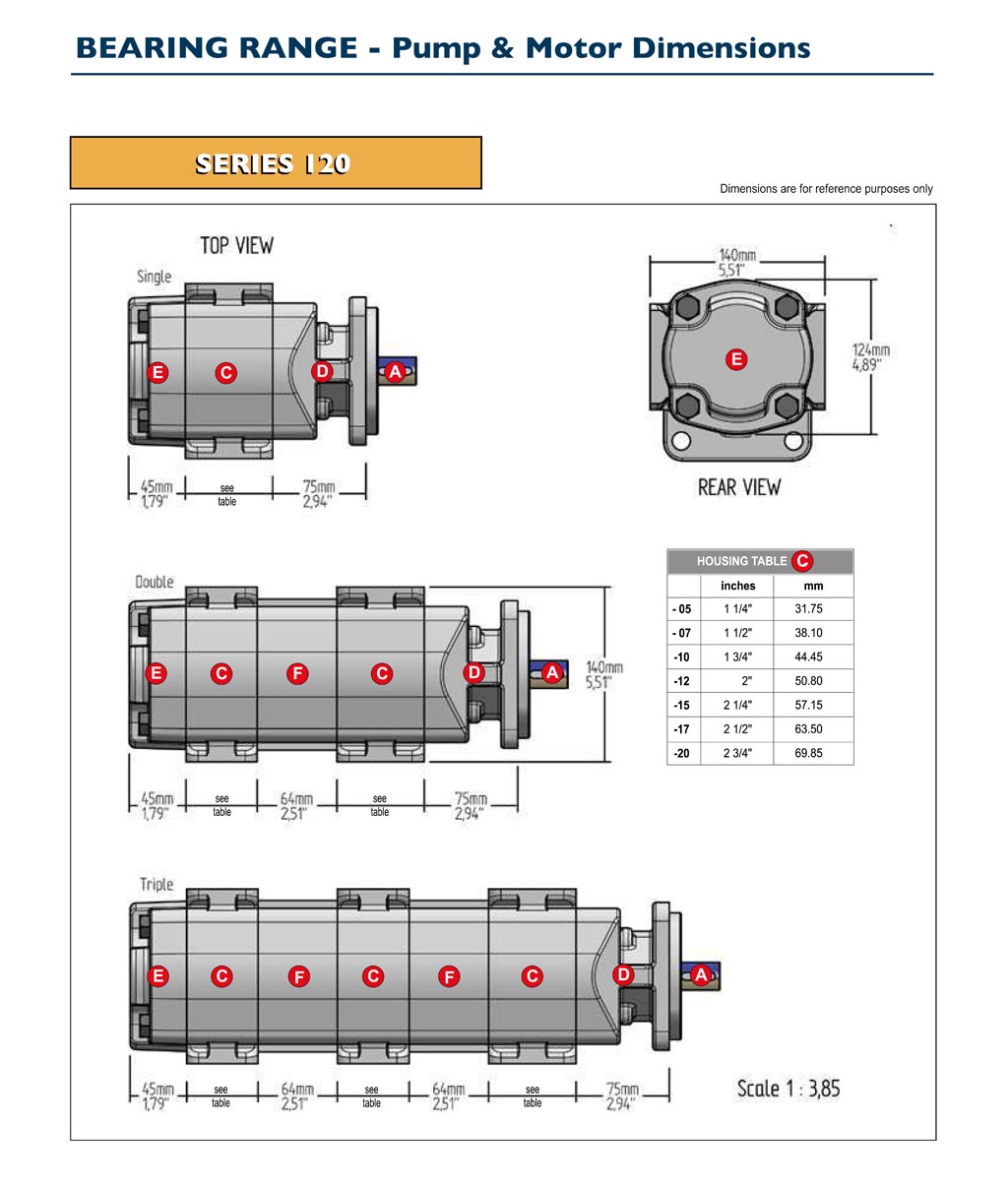

Series 120 Series 125

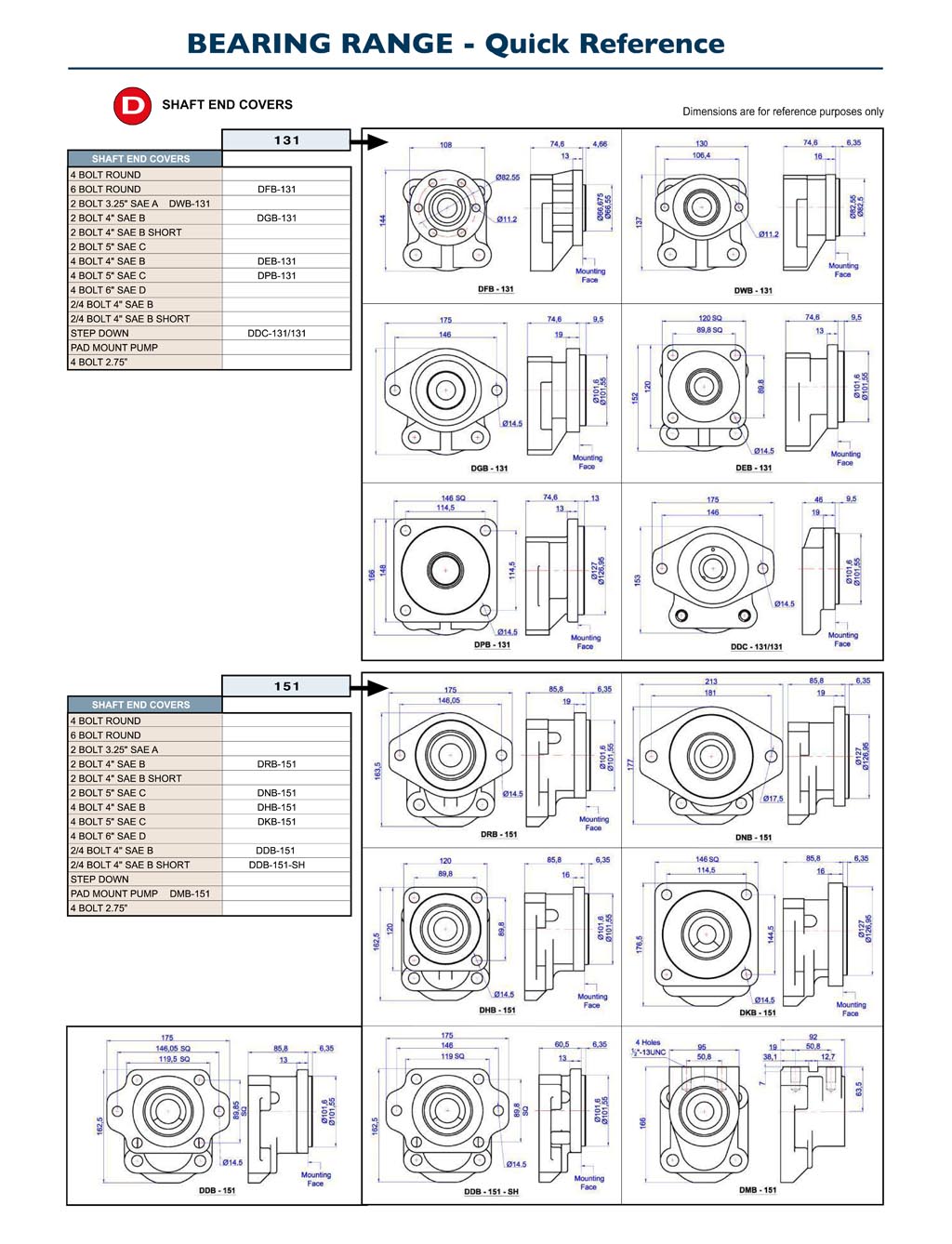

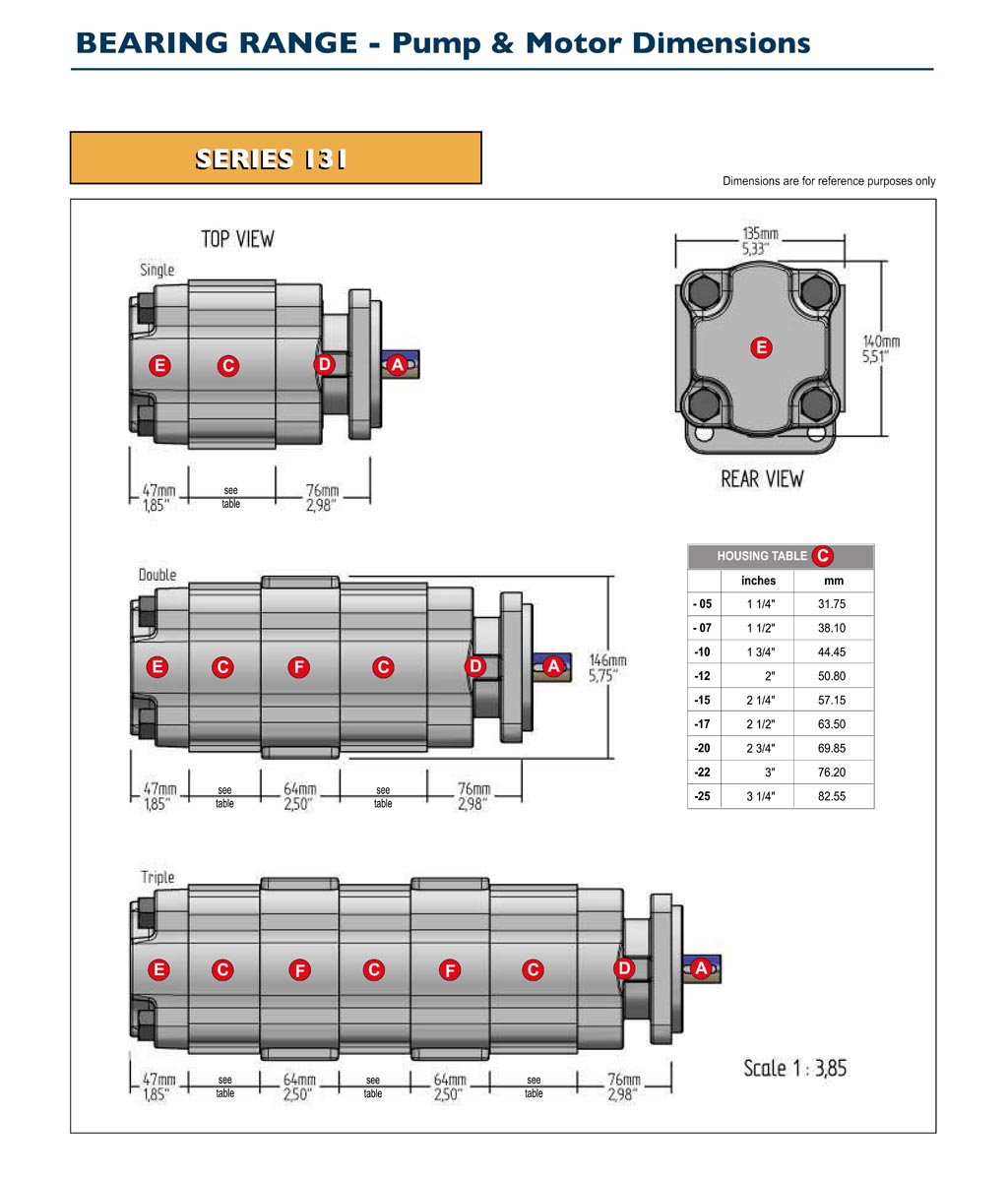

Series 130 Series 131

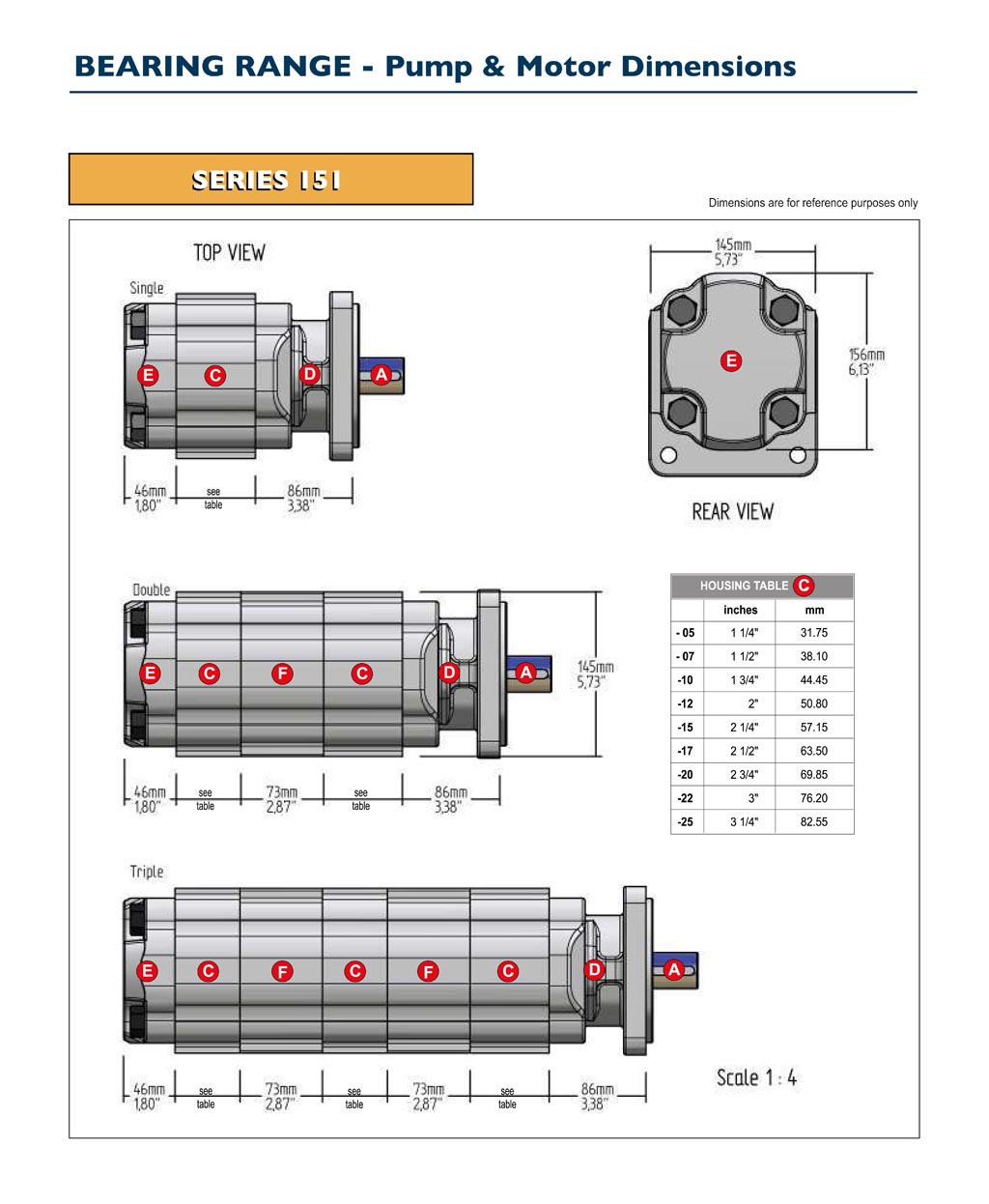

Series 150 Series 151

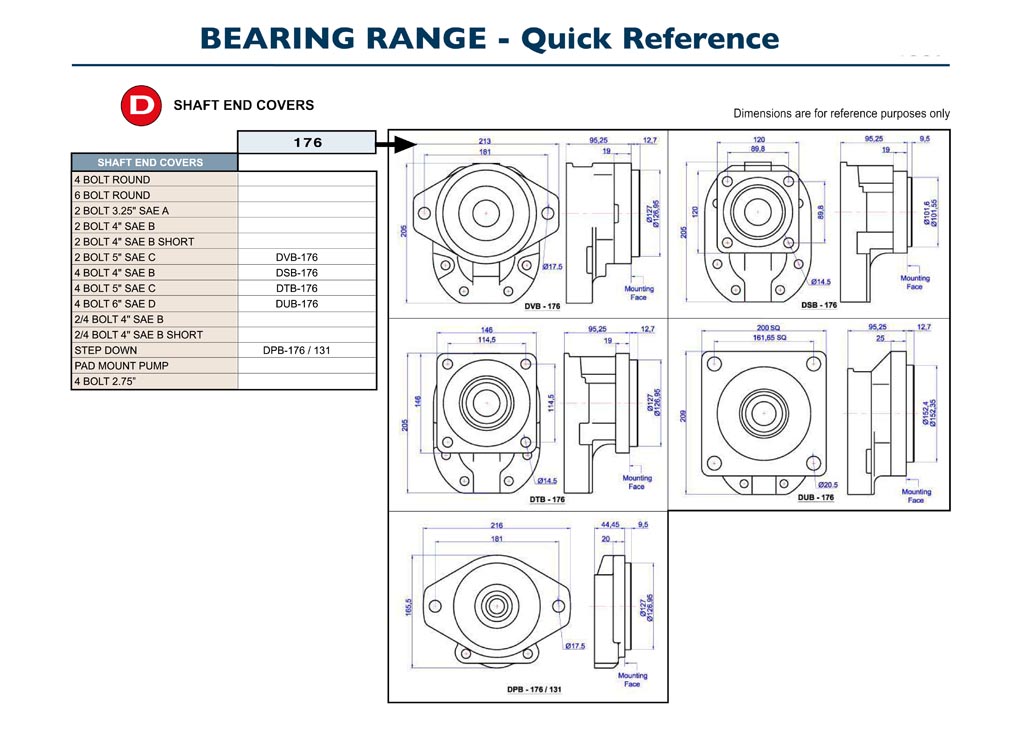

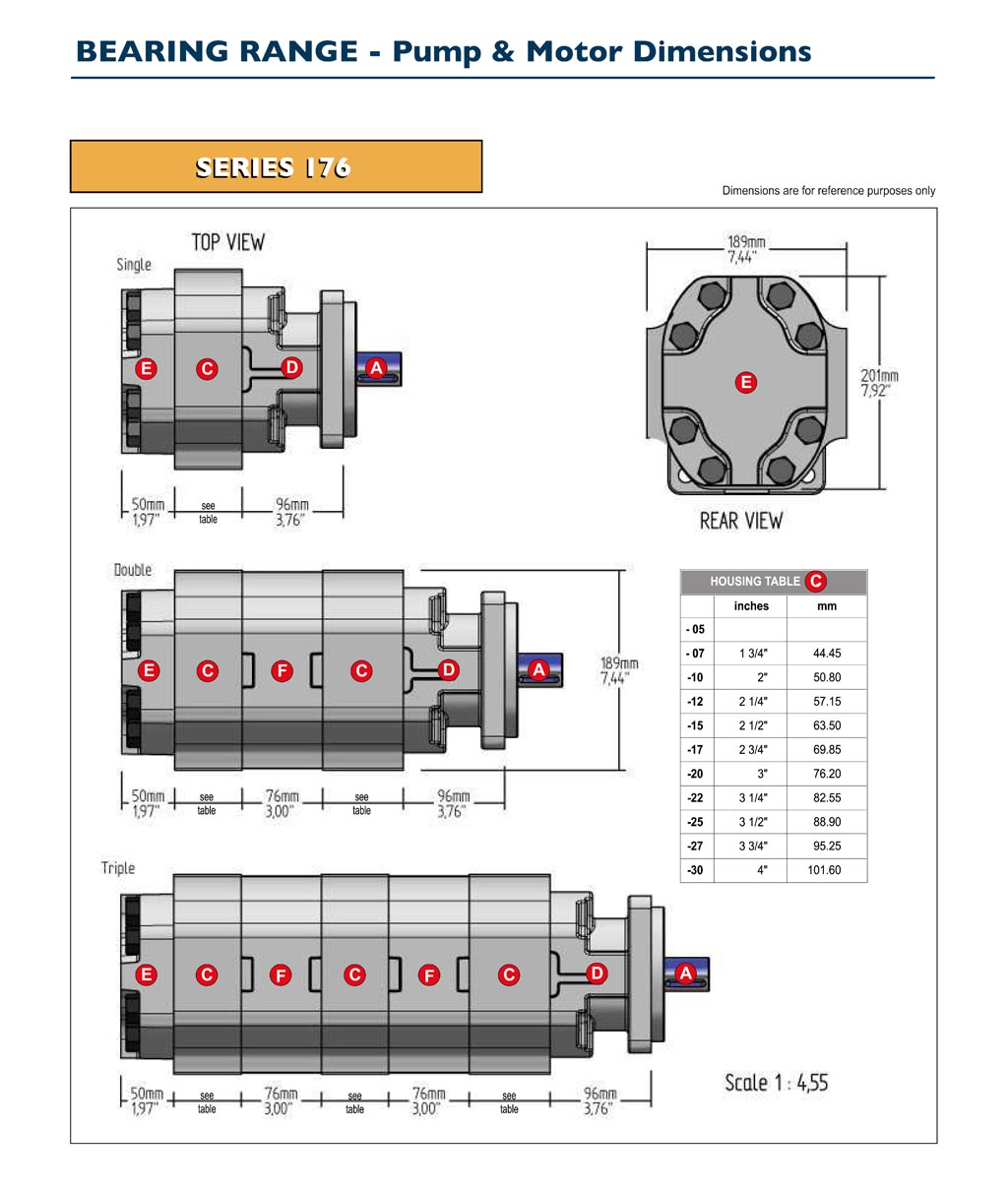

Series 175 Series 176

Hydraulic

- Pumps

- Motors

- Flow Dividers

- Add-a-Pumps

- Spare Parts

Speeds up to: 2400 RPM

Pressure up to 205 BAR

Displacements between 16cc/rev to 200 cc/rev

Click on the BLUE SHADED headlines to open and close pages

PUMPS & MOTORS

Fluid Power for Mobile Equipment

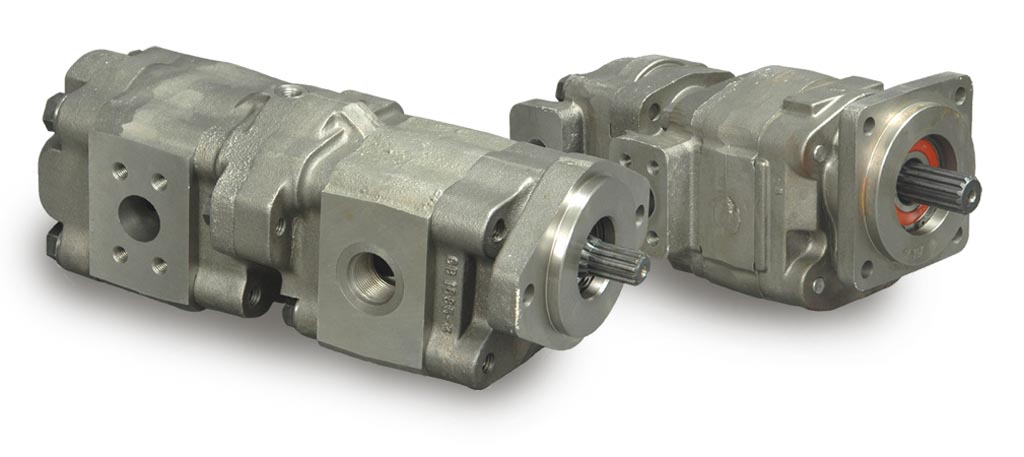

GPM hydraulic pumps and motors are particularly well suited to mobile equipment applications; they are designed for extreme duty cycles, and continuous heavy duty operation. Whilst the equipment is of a simple yet rugged design, it is manufactured to extremely precise tolerances.

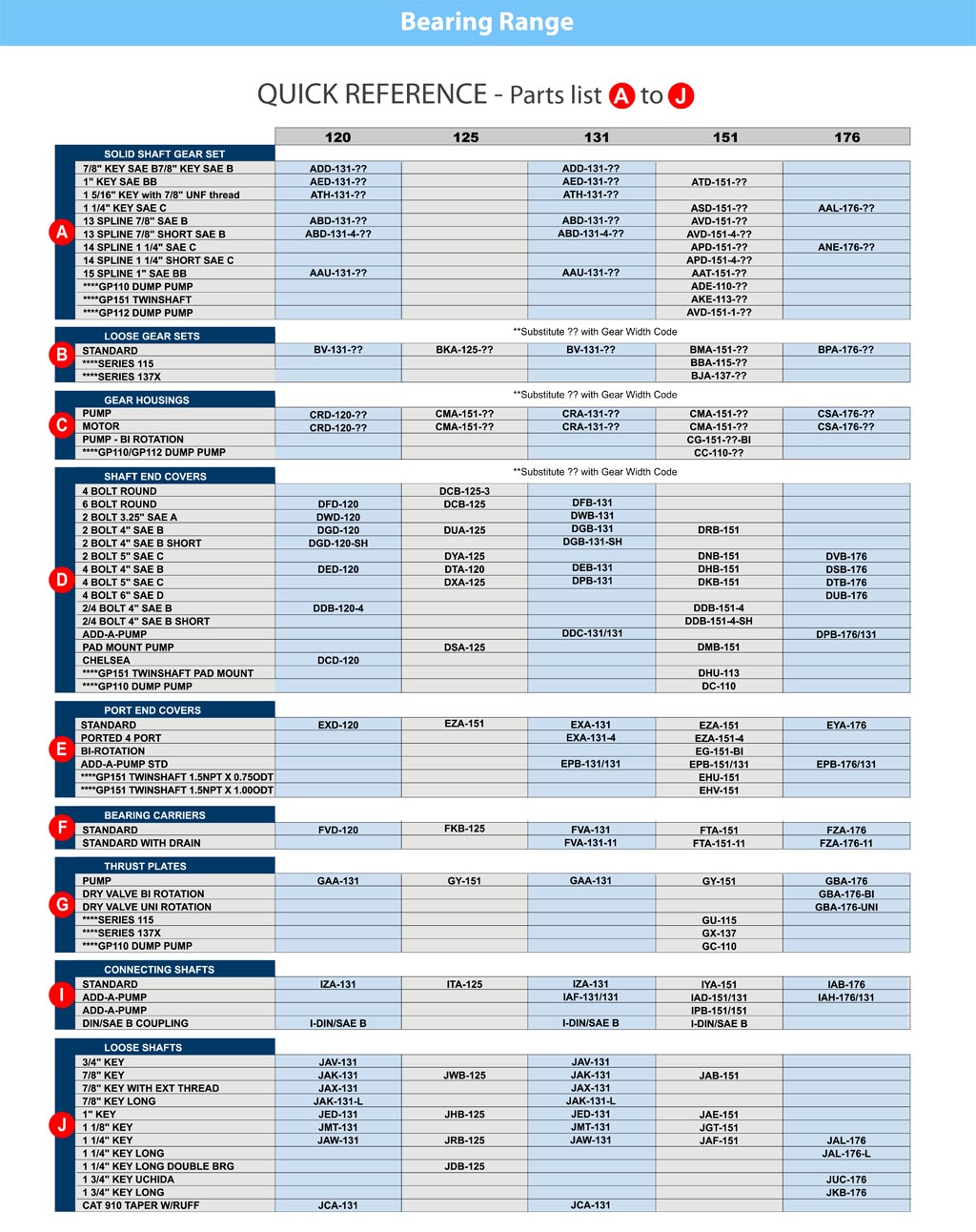

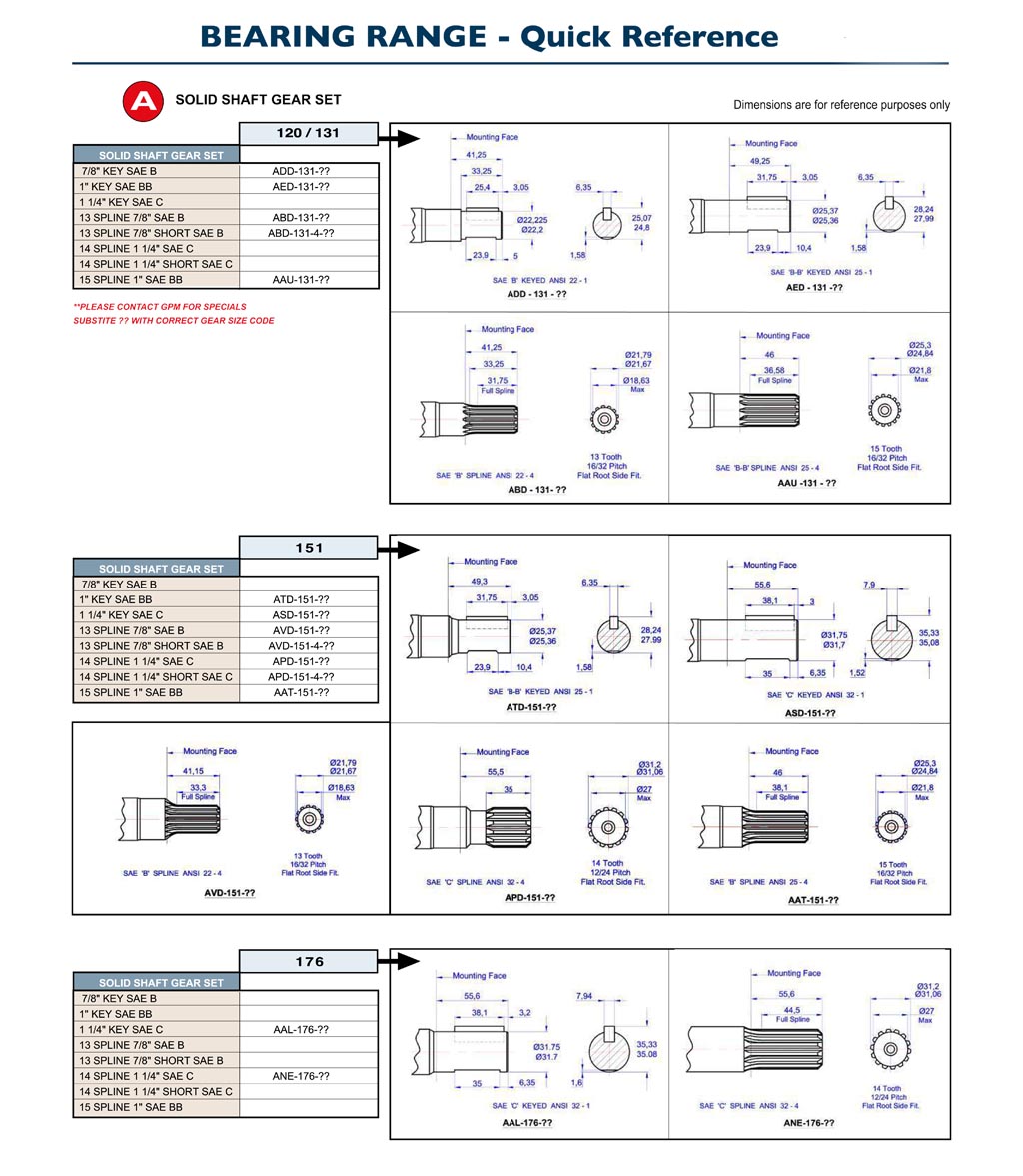

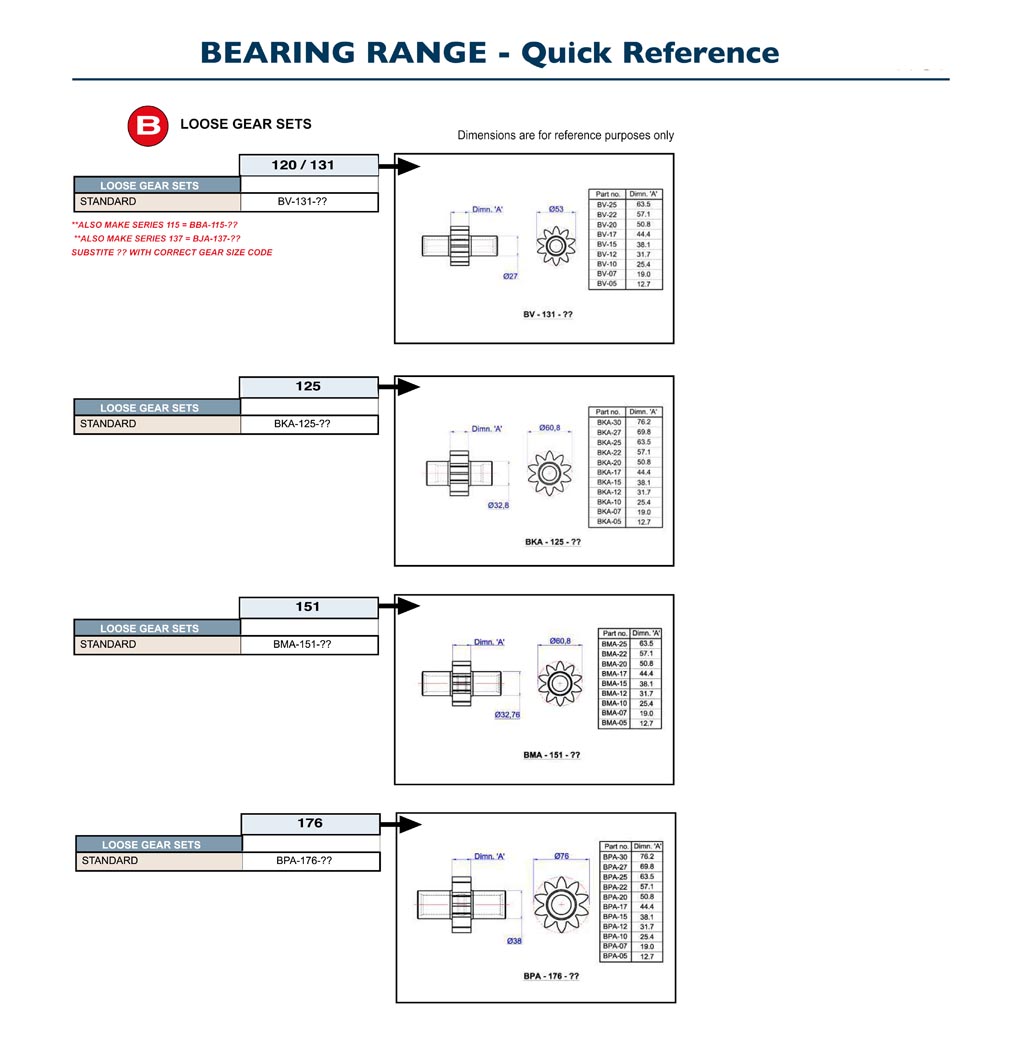

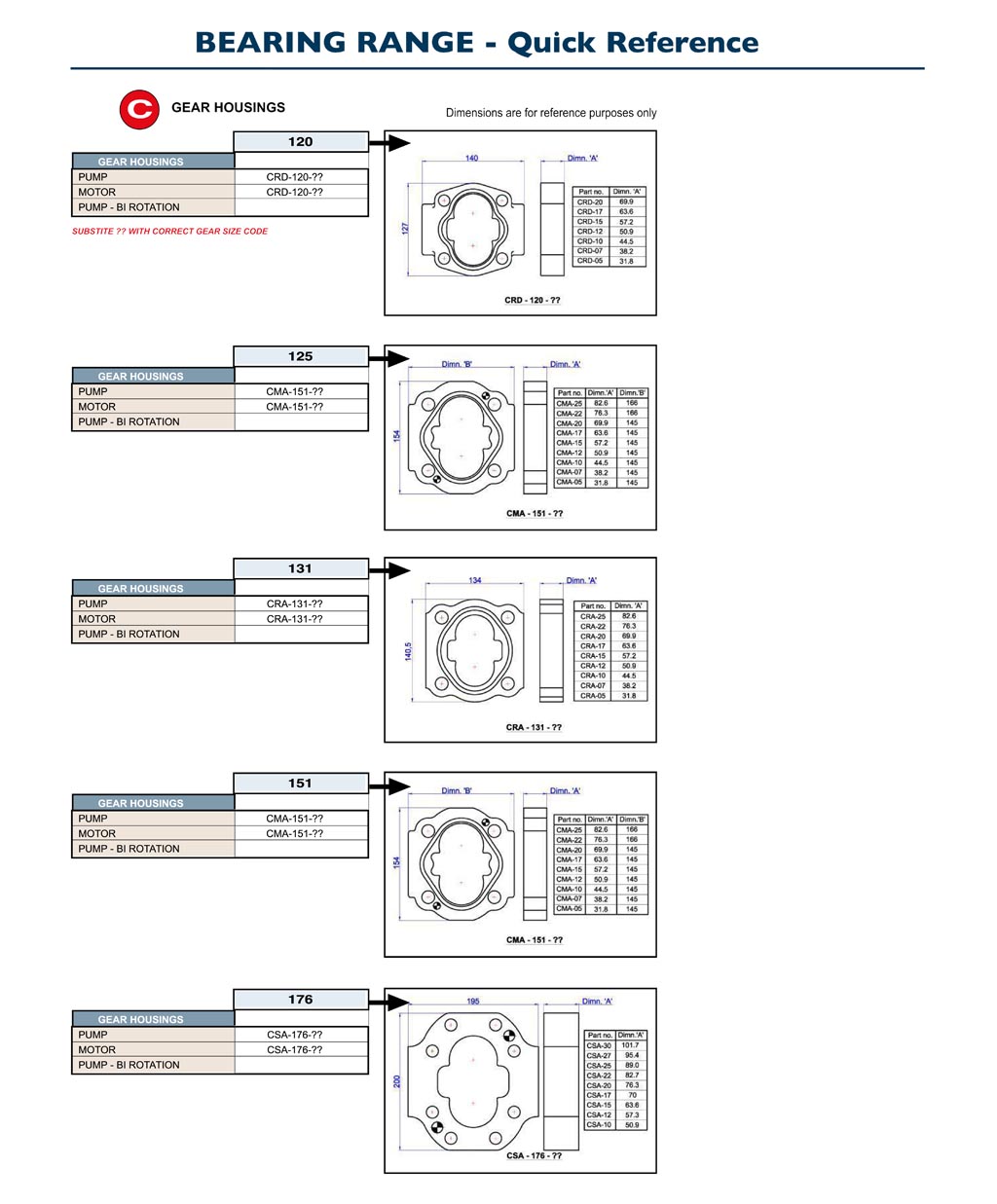

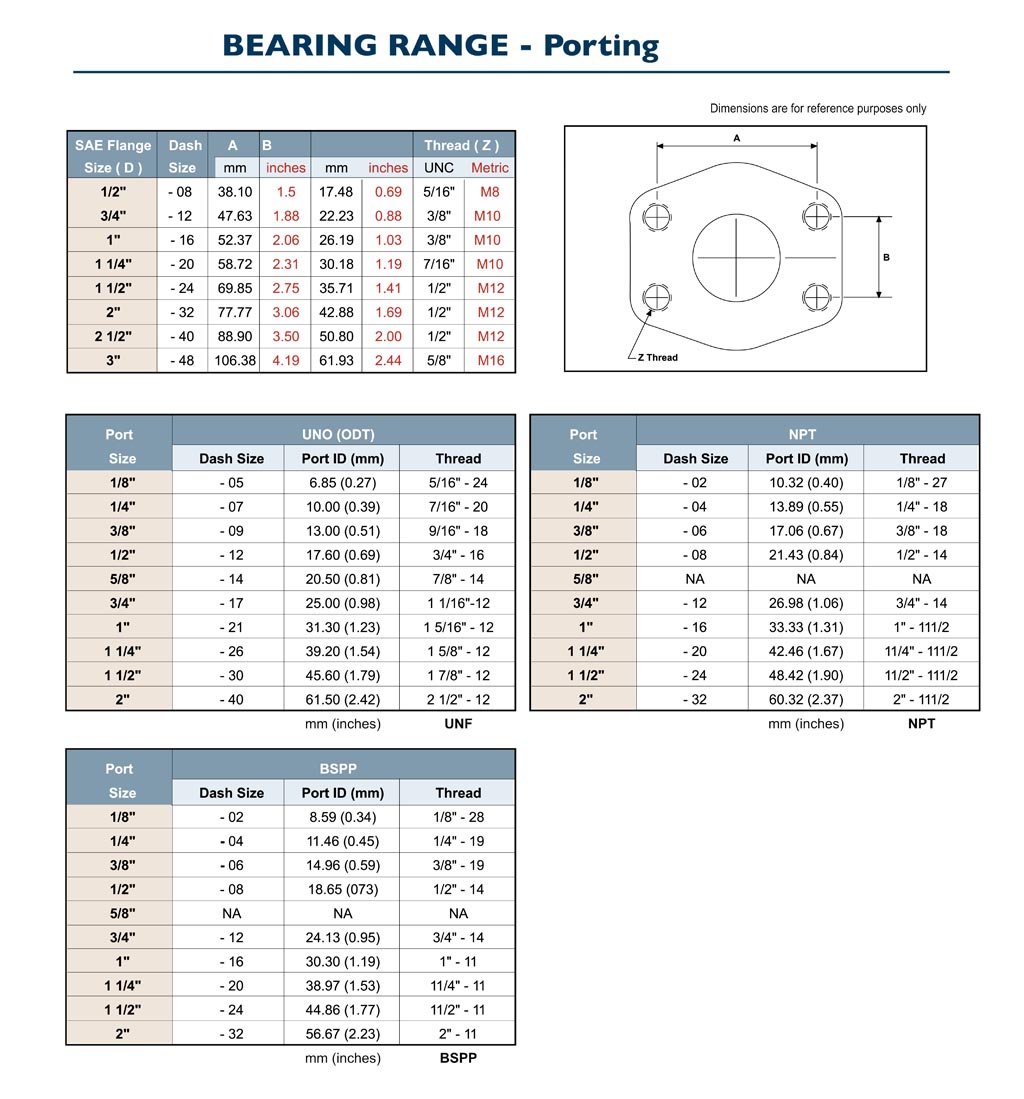

Pumps are available in capacities ranging from 11 cc/rev to 200 cc/rev for each gear section. Several sections can be combined into one assembly. A wide selection of SAE and ANSI mounting flanges and drive shafts are available for all drive units. Pipe thread, 0-ring seal, and split flange ports are available in both metric and SAE standards.

GPM pumps are manufactured under statistical analysis process control which is monitored by the South African Bureau of Standards to an ISO 9001-2008 quality management system.

Major Features

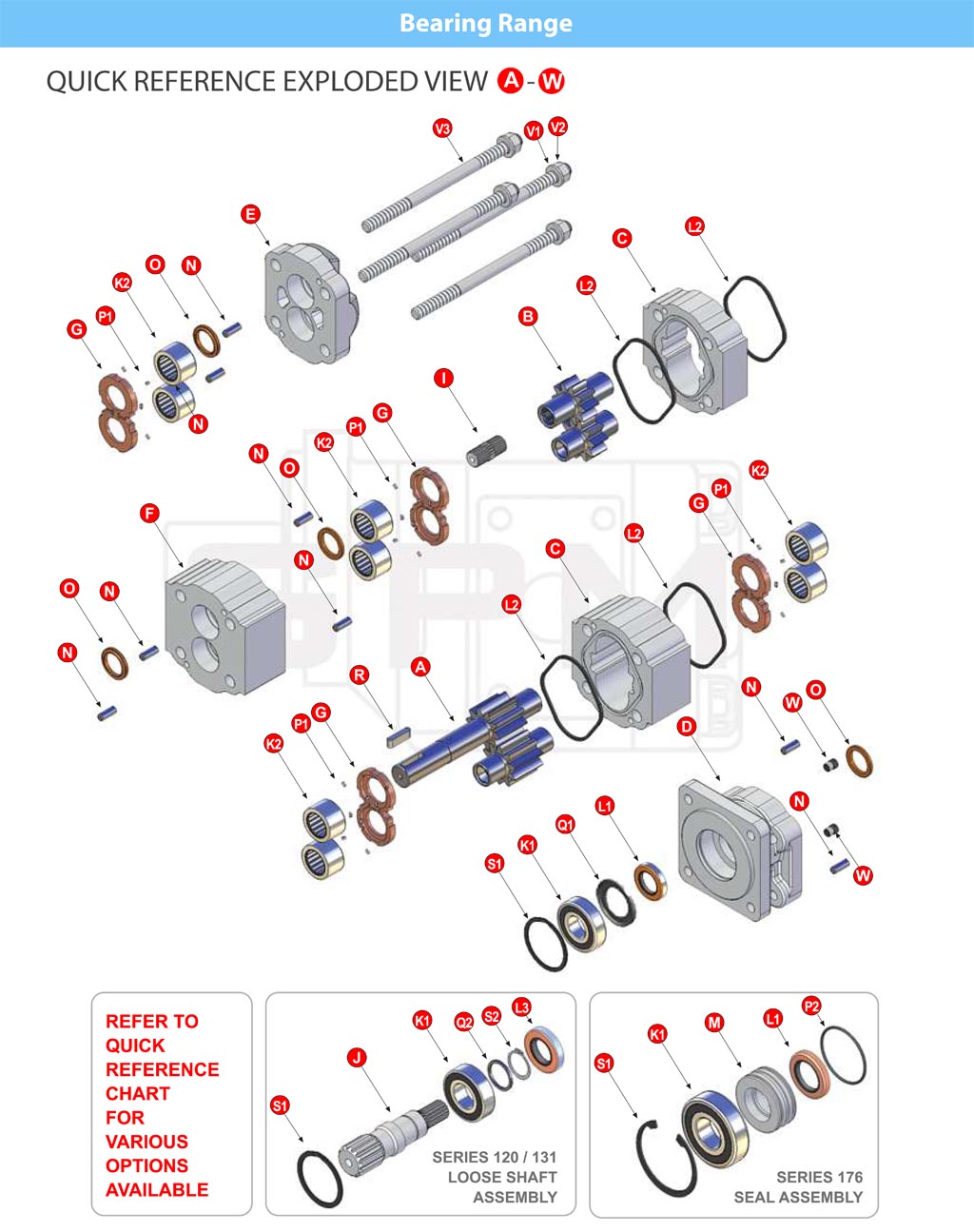

Sectional Construction: Standard parts, cast from high strength grey iron, can be assembled in a wide variety of configurations to suit almost any application.

Multiple pump units: Several pump sections can be combined in a single drive to eliminate multiple drive P.T.O units.

Precision matched gears: All gears are manufactured from high alloy forged bars, surfaces are precision finished and each gear pair is matched for maximum efficiency. The deep 1 0-tooth pattern gives maximum output per revolution whilst ensuring low pulsation frequency.

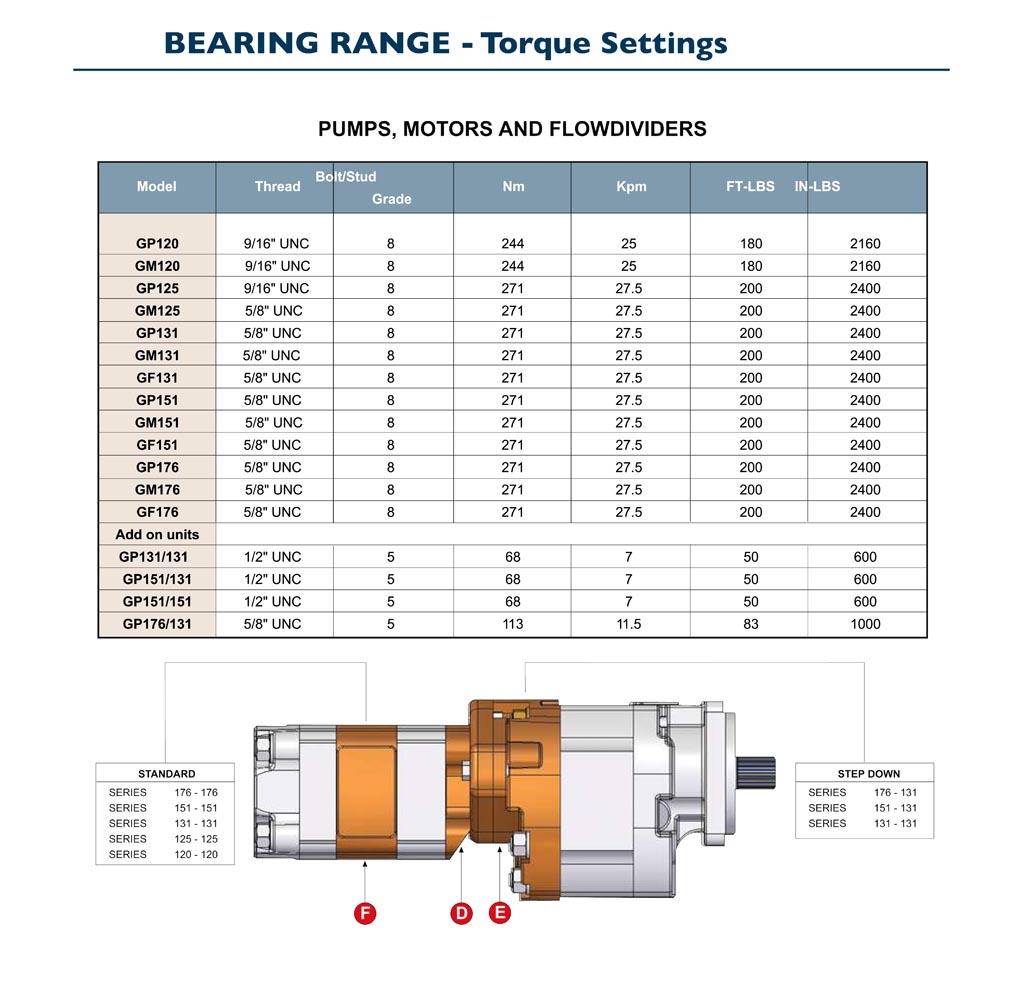

Bearings: Heavy duty roller bearings are utilized on all gear journals to reduce wear caused by contamination.

Motors: are available with capacities ranging from 0. 75kW to 75kW. Basically similar in design to pumps, they are engineered for extreme heavy duty applications, with high efficiency characterists. Motor speed is in direct proportion to the volume of oil delivered to the inlet port and output torque is in proportion to the pressure supplied to the motor. All other equipment required to match our pumps and motors is readily available.

Interchangability

GPM hydraulic equipment is direcUy interchangeable with the other internationally recognized SAE pumps and motors.

GPM equipment is sold in component form but units can be assembled and tested to meet your particular requirements.

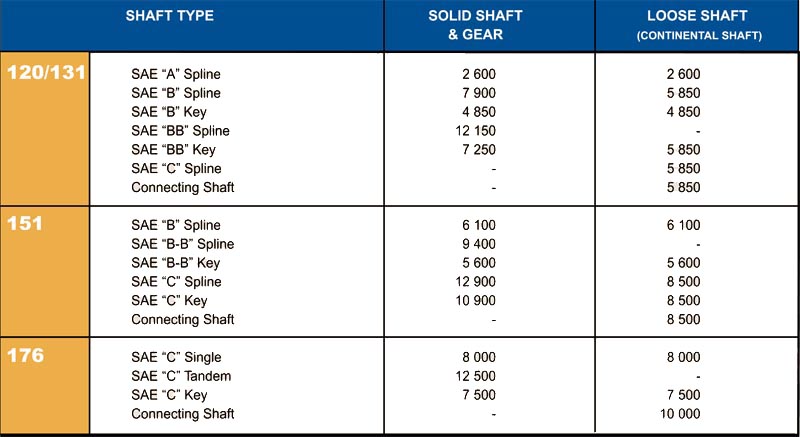

PL Factor

Each section of a pump or motor should be regarded as a single unit with corresponding power input requirements. The entire input horsepower is fed through the drive shaft, the power delivered to or from the unit is limited by the strength of the shaft. The limit is defined as the “PL” factor, the “P” being the operating pressure in PSI and the “L” the sum of the gear widths In Inches.

In multiple units the “PL” must be calculated for each connecting shaft and must include the sum of the gear widths driven by it. (Each shaft has a unique “PL” factor as can be seen in the table below)

Pressure (PSI) x Total Gear Width (Inches) = PL Factor

PL FACTOR MUST NOT EXCEED FIGURE SHOWN IN CHART FOR SHAFT TYPE

Contact us about this Pump Range

Contact Details

Our locations

We are located at: 210 Motor Scooter Drive, Nesbit, MS 38651

Our Worldwide Head Office and Manufacturing Facility is located at 15 Moody Avenue, Epping Industria 1, Cape Town, South Africa. If you are closer to that location and wish to contact them, view their website’s contact page here.

Call us

Our switchboard is open from Monday to Friday from 7:30 – 4:30 Central. Phone: 662 298 3652

Contact Form